What is a peristaltic pump?

Peristaltic pump is one type of positive displacement pump. This pump works by releasing and squeezing a hose. The peristaltic pump has a flexible tube. Fluid pumping is done by creating pressure on a ring of hose by two gears or cams on both sides of the pipe diameter. The rotational motion created by the gears forces the fluid to move. As each leg reaches the end of the tube loop, it returns to its original shape and suction is created in it.

In a simpler way, the peristaltic pump dosing function can be considered dependent on the movement of the diaphragm in the pump head. The reciprocating diaphragm causes the fluid to be pumped. The most important part in this type of pump are the rollers adjacent to the tube. These rollers create a flow inside the hose and transfer fluid through them.

Peristaltic pump is one type of positive displacement pump that has a tube with high flexibility. Peristaltic pumps are divided into three main groups: hose, eccentric 360 degrees and tube. Dosing pumps are very widely used in the industry because they can pump a specific amount of chemicals and fluids to the required location. Peristaltic pump is most used in laboratory, medicine and food industries.

Dosing pump refers to a group of pumps that can transfer a certain amount of fluid from one point to another. Dosing pumps include a large group of pumps with different working methods, all of which work in positive displacement mode. One of the types of dosing pumps is the peristaltic pump.

The peristaltic dosing pump also works with the positive displacement method and is suitable for pumping corrosive and chemical substances. One of the important features of this type of pump, which distinguishes it from other types of dosing pumps, is that the fluid does not come into contact with the internal parts of the pump, because the transfer and pumping are done only in one hose, so this pump is very suitable for corrosive and chemical substances.

In general, dosing pumps are designed to move a limited volume of materials. Peristaltic pump is no exception to this rule. Of course, in peristaltic high pressure pumps, the device can work under a maximum pressure of 16 bar, which makes it suitable for selected industrial uses.

How is the peristaltic pump different from other dosing pumps?

One of the distinguishing features of peristaltic is that it does not have a pulse when transferring liquid and moves it continuously, while most dosing pumps, because they work with an impact method, have a discontinuous operation. The suction power of peristaltic pumps is much higher than that of dosing pumps.

The maximum production pressure in the low-pressure peristaltic dosing pump is 4 bar. This pump tolerates less pressure due to the tubes used in its structure; Because at high pressure, these tubes lose their flexibility and as a result, the fluid does not move. Of course, in peristaltic high pressure pumps, the device can withstand up to 16 bar pressure.

Finally, peristaltic pumps are cheaper than dosing pumps because they do not require mechanical seals or seals. This issue makes them have a lower price when buying and their maintenance costs are reduced during use.

The difference between peristaltic pump and other dosing pumps

Most peristaltic pumps have more limitations in adjusting the amount of liquid transfer than dosing pumps. The pump’s dosing capability is more adjustable and a device can perform a more diverse range of fluid transfer than the peristaltic pump, but the peristaltic pump is more suitable for low transfer doses.

Finally, although the peristaltic dosing pump is one of the types of dosing pump, it is more specialized for use in laboratory, medical and food industries; While other dosing pumps mainly have industrial applications and are used for chlorination, lime injection or antiscalant in water and sewage and oil and gas industries.

Main components of peristaltic pump

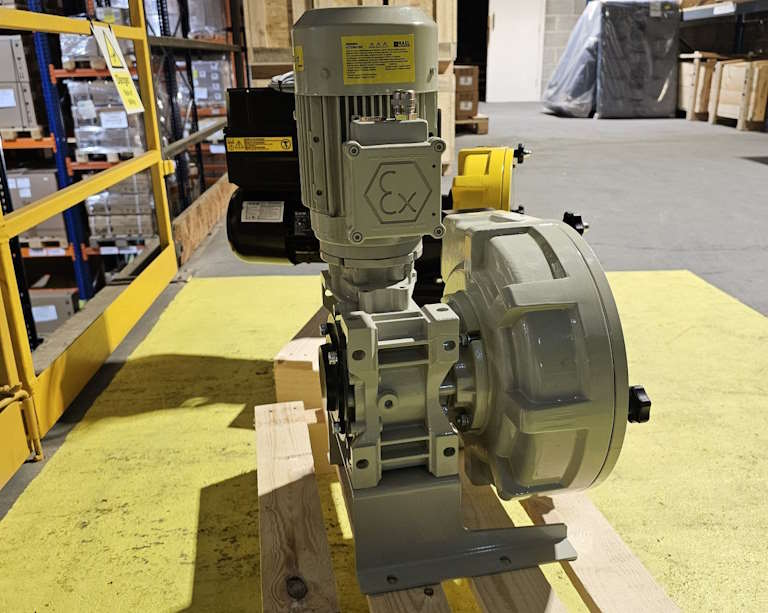

Peristaltic consists of three main components, which include pump driver, pump head and flexible hose. The pump driver refers to the engine assembly of the device, display, engine speed control system, inputs and outputs, and their holding box.

The pump head is the part of the device that is rotating. The pump head is connected to the machine’s motor shaft and has several rollers. These rollers create a vacuum by putting pressure on the hose body; As a result, the liquid is transferred from one side of the flexible hose to the other side. This flexible hose, which is usually made of silicone, is soft and flexible, and because of this, it is easily flexed by the pump head and returns to its original state after passing through the roller.

Types of peristaltic dosing pumps

This type of pump can be classified in two ways. The first method in terms of fluid transmission system and the second method in terms of pressure is to use a pump. The criteria for classifying pumps in terms of fluid transmission system is the type of hose used in it. Peristaltic pumps are divided into three categories: hose, tube, and 360-degree eccentric.

Hose peristalsis can create a maximum pressure equal to 16 bar. This pump uses a roller at low pressures and a shoe at high pressures to create the necessary pressure to transfer the fluid. Hose pumps have special oil chambers to reduce heat loss and prevent wear in the tube.

Peristaltic pumps are divided into two groups in terms of working pressure, which includes high-pressure pumps and low-pressure pumps. High pressure peristaltic dosing pump is used when the pressure on it is more than 16 bar.

Fluid transfer in high pressure pumps

High pressure pumps transfer fluid using shoes. To prevent damage to the exterior and control heat during the process, this type of pump has a chamber of oil and lubricants. In this type of pump, reinforced pipes are used to control the high pressure in the hose during transfer.

Low pressure pumps usually have dry seals and depend on rollers to convey fluid. Because the pressure applied to the transmission hose is low, there is no need to use reinforced pipes in this type of pump.

What are the peristaltic dosing pump components made of?

The body of peristaltic pumps is made of stainless steel. The purpose of choosing this material is to reduce friction in the pump as much as possible. The use of stainless steel also increases the life of the pump. In the industrial samples of this product, alloy cast iron is used, which has more resistance, but for pumps that are used in laboratory scale and non-heavy use, dry plastic body is also available.

The use of dry plastic, which is common in peristaltic centrifugal pumps, reduces the general weight of the device. The hoses in this type of pump are made of Viton, EPDM, NBR, neoprene, PPT, PVC, silicone and polyurethane.

What are the advantages of peristaltic pump?

The peristaltic dosing pump has several advantages that have made it widely used in the industry. This pump can continue to work without fluid inside the hose, and unlike most pumps, running dry does not cause wear and tear.

One of the most outstanding mechanical features of this pump is the lack of mechanical sealing and high suction ability. The lack of mechanical sealing in this pump reduces the need for maintenance. The high suction ability of the pump makes it suitable for use in viscous fluids and increases the pump’s operating range.

Peristaltic pumps, which move fluid through a plastic hose, can move highly toxic and abrasive materials without wearing out. For this reason, in industries that cannot use pumps with steel or cast iron bodies due to abrasiveness or chemical characteristics of materials, they are considered a suitable alternative, especially because they have very high operating accuracy.

What should we pay attention to when buying a peristaltic pump?

In order to buy a peristaltic pump that meets our needs and is optimal and economical compared to the budget we consider for it, we must check some of the features of the pump before buying and adapt it to our needs. If needed, it is even better to get advice from an expert to be sure that we have made a good purchase.

Below is a list of variables that you should consider when buying a peristaltic dosing pump, which includes the following:

- The minimum and maximum flow required

- Injection accuracy

- Hose material

- How to control flow (analog or digital)

- Pump working voltage

Where is the peristaltic dosing pump used?

This type of pump is used in various industries such as food, pharmaceutical and chemical. For example, this pump is used in animal farms to inject medicine to animals and in fish farms to feed aquatic animals. Another application of peristaltic pump is in medicine, where it is used for dialysis or blood transfusion.

Transferring fluid from one point to another is one of the applications of pumps in various industries, for example, peristaltic dosing pumps are used to transfer creams, color glues, ampoules, and medicinal drops. In industries that work with viscous fluids, peristaltic pumps are also used to transfer cement or paper pulp. All the mentioned examples indicate the diverse use and importance of this pump in different sectors of the industry.

Peristaltic pump maintenance

Peristaltic dosing pumps require very little maintenance. One of the conditions that is necessary in the maintenance of peristaltic dosing pump is regular service, which prevents the occurrence of major problems in the pump. In general, if this type of pump has normal working conditions, i.e. it does not need to work very hard, it rarely needs to be repaired. Providing the main parts, sufficient equipment and skilled repairman is necessary to maintain the life span and non-depreciation of the pump.

Conclusion

A peristaltic dosing pump is a positive displacement pump that operates by releasing and squeezing a hose. Peristaltic pump consists of three main components, which include pump driver, pump head and flexible hose.

This type of pump can be classified in two ways. First, the fluid transfer system and second, the pump operating pressure. Peristaltic pumps are divided into three categories: hose, tube, and 360-degree eccentric. Peristaltic pumps are divided into two categories in terms of working pressure, which includes high-pressure pumps and low-pressure pumps. The maximum pressure tolerable for the peristaltic pump is 16 bar. This pump is often used in laboratory, medical and food industries.

Below is a list of variables that you should pay attention to when buying a peristaltic dosing pump, including the minimum and maximum required flow rate, injection accuracy, hose material, flow control method (analog or digital) and pump working voltage.